Why Magnesium Stearate Matters?

Introduction: The Unsung Hero in Every Supplement

When you pop a tablet or capsule, you rarely think about what goes into making it. But at Shine Health, we obsess over every detail. We manufacture Magnesium Stearate as Lubricant because it’s one of the most vital—yet invisible—ingredients in tablet production. It doesn’t deliver the nutrients, but it makes sure they get to you intact, fast, and fuss-free.

In this article, we’ll pull back the curtain. You’ll learn how it works, why we trust it, and what the science really says about this powdered powerhouse.

What Is Magnesium Stearate?

A Breakdown of Its Basics

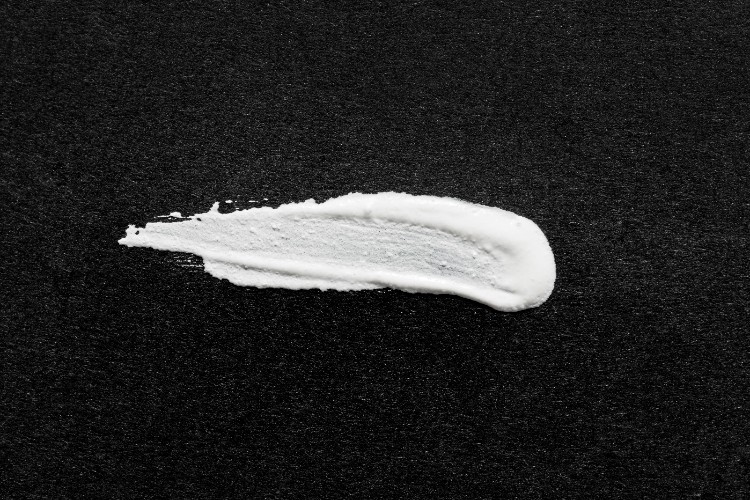

Magnesium Stearate is a fine, white powder. We create it by blending magnesium with stearic acid—a fatty acid often sourced from palm oil or other plant fats. Despite being used in small amounts (typically less than 1% of a formula), its effect on the final product is enormous.

You won’t find it on the label in bold letters. But without it, your supplement might not even exist in solid form.

What It Looks Like Chemically

Its molecular structure is unique: one magnesium ion bonded with two stearate (fatty acid) ions. That gives it a waxy texture and water-repelling properties, making it ideal for keeping things flowing and non-sticky during tablet compression.

Is It Safe?

Yes. In fact, Magnesium Stearate is generally recognized as safe (GRAS) by global health authorities, including the FDA and EFSA. It’s been widely used for decades, and despite online rumors, it’s not toxic, not carcinogenic, and certainly not a health threat when used appropriately.

What Does Magnesium Stearate Do in Tablets?

The Silent Worker in Manufacturing

Here’s where it shines. During tablet production, ingredients get compressed with immense force. That pressure generates friction—lots of it. Without a proper lubricant, the tablet press would overheat, parts would stick, and tablets would crack or shatter.

Magnesium Stearate reduces this friction. It coats ingredients in a slick layer, helping the mix glide smoothly through equipment and eject cleanly from molds. It directly impacts ejection force, powder flow, and tablet properties like hardness and consistency.

Direct Benefits in Production

We’ve worked in this space for years, and we’ve seen firsthand how this simple powder transforms tablet manufacturing:

· Reduces sticking during compression

· Improves flow of powders during mixing

· Ensures uniform filling of tablet dies

· Prevents cross-contamination between tablet batches

· Preserves delicate active ingredients

· Enhances the mechanical strength of the finished tablet

The Effect of Magnesium Stearate on Tablets

Let’s Talk Tablet Properties

When used correctly, Magnesium Stearate has the following effects:

· Reduces ejection force so tablets release cleanly

· Improves surface finish and visual appearance

· Helps maintain tablet shape and durability

· Slightly affects disintegration times—but within acceptable ranges

That last point is important. While it may slow disintegration by a few seconds, we counter that by optimizing other excipients and mixing methods. At Shine Health, we fine-tune this balance every day.

Why Particle Size Matters

Particle size isn’t just a detail. It’s a game changer. Finer particles cover more surface area, creating better flow. But if they’re too fine, they might block tablet pores and slow down breakdown.

We use controlled particle sizes between 6–12 microns, which allows us to hit the sweet spot between flowability and quick release.

Tablet Formulations We Build With It

Versatility Is the Name of the Game

Here are just a few formulations we optimize with Magnesium Stearate:

· Multivitamins

· Digestive enzymes

· Calcium and magnesium supplements

· Probiotic tablets

· Herbal extract capsules

· Functional food blends

In each case, we measure the lubricant’s effect on flow, compressibility, and breakdown. And guess what? The results always speak for themselves.

Materials and Methods We Follow

We don’t guess—we test. Our R&D team uses a strict materials and methods approach. Here's our workflow:

1. Pre-screen all powders for particle distribution

2. Dry-blend the core formula

3. Add Magnesium Stearate in the final mix step

4. Run flow rate and compression trials

5. Measure tablet hardness, friability, and disintegration

6. Adjust process parameters based on results

This keeps our output consistent and high-quality across every batch.

Is Magnesium Stearate Just a Filler?

The Truth About “Inactive” Ingredients

Technically, yes—it’s classified as an inactive ingredient or food additive. But we’d argue otherwise. It performs active, functional work. It just doesn’t deliver nutrition.

Think of it like oil in your car engine. It doesn’t drive the car forward, but without it, everything grinds to a halt.

Laxative Effect? Not a Real Concern

Some worry that stearates could cause a laxative effect. But scientific evidence and regulatory reviews show otherwise. You’d have to consume hundreds of tablets at once to feel anything unusual. We use safe limits far below that point—usually just 0.25% to 1%.

Applications Beyond Pharmaceuticals

In Food and Cosmetic Products

You’ve probably consumed Magnesium Stearate without realizing it. It’s used as a food additive to prevent caking and sticking in:

· Baking powder

· Spices

· Candy shells

· Chewing gum

· Instant mixes

In cosmetics, it appears in pressed powders and foundations for its smooth feel and absorbent qualities.

What the Data and Studies Say

Digging into the Research

If you’re a science buff, you’ll love this. Numerous journals and open access platforms have explored the effect of magnesium stearate on tablet properties.

One study showed that tablets made with stearate had 20% less ejection force and maintained 95% of their original mechanical strength after one year of storage. Another paper found that disintegration times increased slightly—but remained within pharmacopoeia limits.

Where to Find Articles and Proof

Here are some trusted resources:

· NCBI – Clinical and toxicological reviews

· ScienceDirect – Formulation optimization case studies

· MDPI – Ingredient performance in functional foods

· FDA Database – GRAS notifications

· Springer – Analytical chemistry in supplement manufacturing

We don’t just rely on theory. We read these journals, run the tests, and apply the learnings directly in our plant.

Final Thoughts from Our Team

Why We Stand Behind Magnesium Stearate

We’ve used this ingredient for years.

We understand its chemistry, its limits, and its role in successful production.

We also know what happens when it’s left out—things fall apart fast.

Our team at Shine Health doesn’t just “add it in” because everyone else does.

We use it because it works. It’s consistent. It’s predictable.

It gives us the quality we want and the peace of mind our customers deserve.

And that’s something we take seriously.

Recap: What You Should Remember

· Magnesium Stearate comes from stearic acid and fatty acids

· It’s generally recognized as safe (GRAS) worldwide

· Improves powder flow, ejection force, and tablet properties

· Used in tablet formulations, food additives, and cosmetics

· Works best in small amounts—typically under 1%

· Has minimal effect on disintegration when used correctly

· Doesn’t cause a laxative effect under normal usage

· Supported by strong materials and methods research

References

1. Magnesium Stearate Functionality – ScienceDirect