How Microcrystalline Cellulose Is Made (and How to Buy the Right Grade)

Microcrystalline cellulose stands as one of the most trusted excipients in solid dosage forms because it is chemically inert, compressible, and consistent. Compared with ordinary powdered cellulose, microcrystalline cellulose is partially depolymerized and enriched in crystalline regions, giving it the flow and binding performance needed for modern tablets, capsules, and coated supplements.

1) Raw materials: why purified pulp matters

At industrial scale, the microcrystalline cellulose manufacturing process starts with high–α-cellulose feedstock—most commonly bleached wood pulp or cotton linters. The goal is to remove lignin, hemicellulose, extractives, and metal ions so the microcrystalline cellulose production process stays stable from batch to batch.

Even when suppliers meet a basic cellulose spec, differences in pulp origin can still change microcrystalline cellulose performance (especially compressibility and flow). That’s why experienced manufacturers lock down pulp viscosity, moisture, brightness, and traceability before hydrolysis.

2) The core step: MCC acid hydrolysis method

If you’re searching “how to make microcrystalline cellulose,” the key is controlled dilute-acid hydrolysis. In the MCC acid hydrolysis method, mineral acid attacks cellulose’s amorphous regions first, while crystalline domains remain—forming the short, rigid particles we call microcrystalline cellulose.

Typical industrial windows (adjusted to pulp reactivity and target DP):

Acid: HCl or H₂SO₄

Temperature: ~60–105 °C

Time: ~10–60 minutes

Solid–liquid ratio: commonly 1:8–1:20 (w/v)

A helpful buyer takeaway: higher “severity” (stronger acid, higher temperature, longer time) generally lowers DP and can increase crystallinity, but it can also reduce yield and create excess fines—both of which affect microcrystalline cellulose tableting behavior.

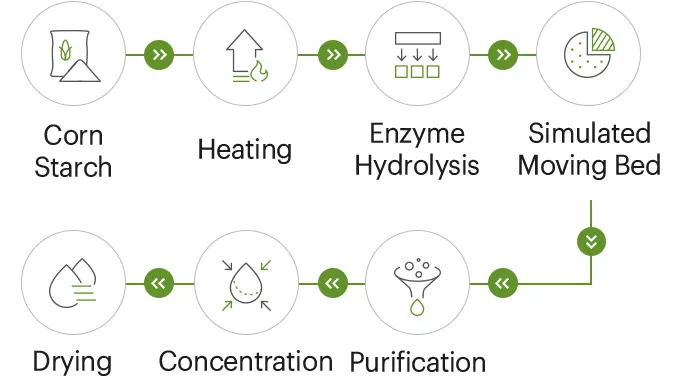

3) Washing, neutralization, drying, and milling: where grades are made

After hydrolysis reaches the “level-off DP” region (commonly cited around DP 150–250), downstream steps define the final microcrystalline cellulose grade:

Washing & neutralization: repeated dilution/filtration or centrifugation to remove acid, soluble sugars, and salts; checks such as conductivity help confirm low residues.

Drying: spray drying is widely used to produce consistent bulk density and flow—important for direct compression.

Milling & classification: controlled particle size distribution enables common commercial grade behavior (for example, PH101-type vs PH102-type performance differences).

In practice, a single wet cake can become multiple microcrystalline cellulose grades by tuning drying conditions and milling intensity.

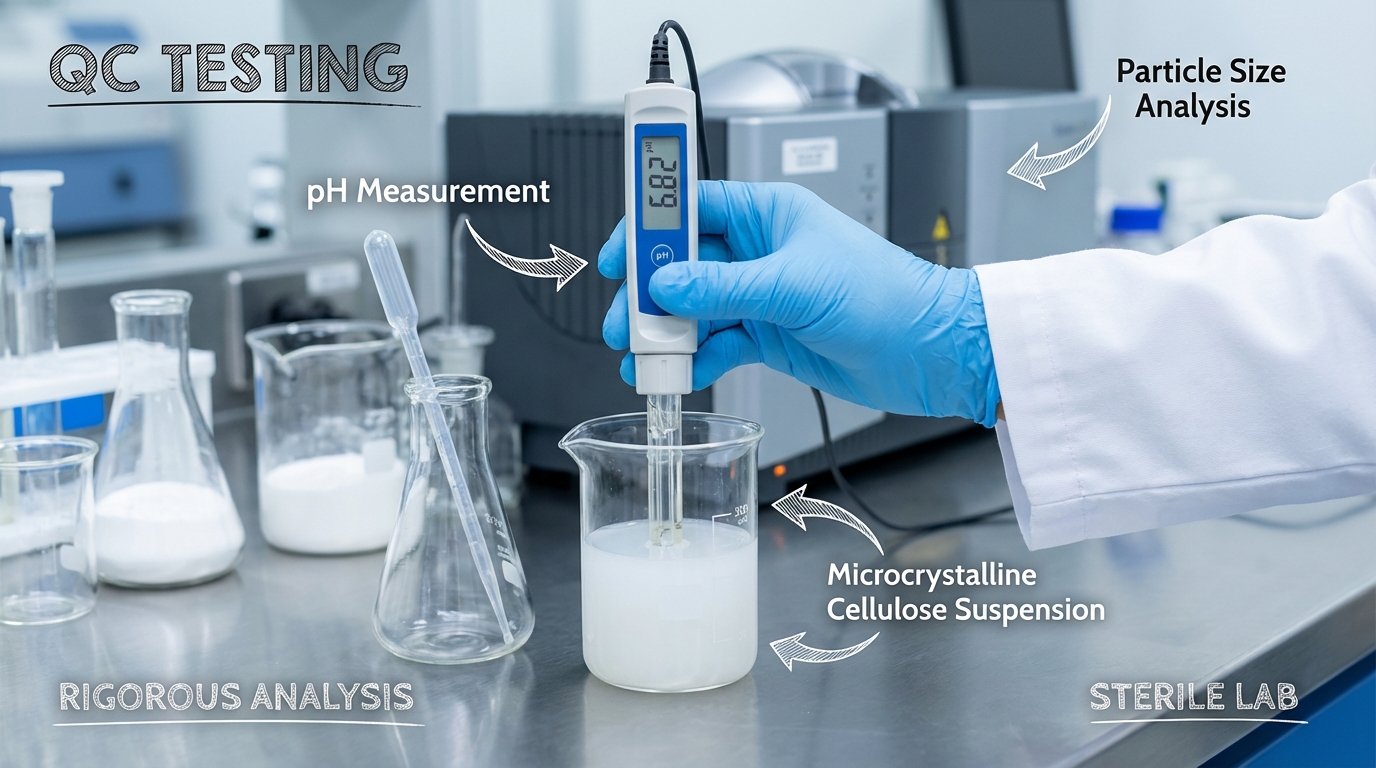

4) Pharmaceutical grade microcrystalline cellulose: QC tests buyers should request

Pharmaceutical grade microcrystalline cellulose is typically supplied against USP/Ph. Eur. monographs, and buyers should insist on batch-level COAs.

Key microcrystalline cellulose quality control tests (and why they matter):

| Test | Why it matters for microcrystalline cellulose |

|---|---|

| Identification (e.g., IR; sometimes XRD used in characterization) | Confirms cellulose structure and crystallinity profile |

| Loss on drying | Moisture impacts flow, stability, and microbial risk |

| pH (suspension) | Flags residual acid/alkali and potential incompatibilities |

| Particle size distribution | Directly drives flow, compressibility, mouthfeel |

| Bulk/tapped density | Impacts die fill, tablet weight uniformity |

| Residue on ignition / ash | Tracks inorganic contamination and process residues |

| Chloride / sulfate (as applicable) | Verifies washing effectiveness |

| Microbial limits | Critical for oral dosage safety |

5) Choosing a Recommended Chinese Microcrystalline Cellulose Manufacturer

When evaluating a Recommended Chinese Microcrystalline Cellulose Manufacturer or a Recommended Chinese Microcrystalline Cellulose Supplier, focus on practical evidence:

Documented specifications tied to pharmacopeial methods

QC capability for identity, density, PSD, moisture, and microbiology

Clear change-control and retained-sample policy

Audit readiness and technical support for formulation work

For instance, Shandong Shine Health operates a 30,000 m² facility with a GMP production workshop and R&D laboratory, supplying excipients and microcrystalline cellulose solutions for tablets and capsules. For sourcing teams also consolidating fiber ingredients, the same evaluation approach often applies when looking for a Recommended Chinese Resistant Dextrin Manufacturer.

Inquiry link: Contact our team for a COA, spec sheet, or sample request.

FAQ

Q: Can microcrystalline cellulose be made from bamboo or bagasse?

A: Yes—any high–α-cellulose pulp can work. However, the microcrystalline cellulose manufacturing process must be re-tuned because different pulps hydrolyze at different rates.

Q: What’s the difference between microcrystalline cellulose PH101 and PH102?

A: Both are microcrystalline cellulose grades. In general terms, PH101 is coarser with lower bulk density, while PH102 is finer/denser and often preferred for direct compression.

Q: How do we scale “how to make microcrystalline cellulose” from lab to plant?

A: Keep the effective acid-to-cellulose ratio, temperature profile, and residence time consistent, then validate washing, neutralization, and powder handling at pilot scale before full production.

References

Miljković, V., Nikolić, L., & Miljković, M. (2024). Microcrystalline cellulose: A biopolymer with diversiform applications. Cellulose Chemistry and Technology. https://doi.org/10.35812/cellulosechemtechnol.2024.58.62

Li, J., Zhang, X., Zhang, M., Xiu, H., & He, H. (2014). Optimization of selective acid hydrolysis of cellulose for microcrystalline cellulose using FeCl3. BioResources, 9(1), 1334–1345. https://doi.org/10.15376/BIORES.9.1.1334-1345

Karim, M. Z., Chowdhury, Z. Z., Hamid, S. B. A., & Ali, M. E. (2014). Statistical optimization for acid hydrolysis of microcrystalline cellulose and its physicochemical characterization. Materials, 7(10), 6982–6995. https://doi.org/10.3390/ma7106982

Valchev, I., Yavorov, N., & Todorova, D. (2020). Producing bleached microcrystalline cellulose by two-stage dilute acid hydrolysis. Cellulose Chemistry and Technology. https://doi.org/10.35812/cellulosechemtechnol.2020.54.27

Kazakova, E. G., & Demin, V. A. (2009). A new procedure for preparing microcrystalline cellulose. Russian Journal of Applied Chemistry. https://doi.org/10.1134/S1070427209030276

Younes, M., Aggett, P., Aguilar, F., et al. (2018). Re-evaluation of celluloses (E 460(i)–E 469) as food additives. EFSA Journal, 16(1), e05047. https://doi.org/10.2903/J.EFSA.2018.5047

Tan, W. Y., Gopinath, S. C. B., Anbu, P., et al. (2023). Generation of microcrystalline cellulose from cotton waste and its properties. BioResources, 18(3), 4884–4896. https://doi.org/10.15376/biores.18.3.4884-4896