Green Roadmap for MCC and Resistant Dextrin

Overview — practical, measurable decarbonisation for functional fibers

Shine Health has developed a pragmatic roadmap to cut life‑cycle greenhouse gas intensity (kg CO2e/kg), energy (MJ/kg) and freshwater use for two strategic product lines: microcrystalline cellulose (MCC) and resistant dextrin. The approach combines immediate measurement, short cradle‑to‑gate LCA pilots, feedstock trials (corn vs tapioca), targeted process intensification and utility circularity measures. The goal is simple: set a baseline, pursue high‑impact engineering changes first, then scale what works.

Measured baseline and short LCA pilots (0–6 months)

Start with a clear functional unit: 1 kg product (cradle‑to‑gate) and report: kg CO2e/kg, MJ/kg energy, m3 water/kg and % chemical reuse. Run a 0–6 month pilot combining plant metered energy, steam and water data with a short LCA comparing corn and tapioca starch as feedstocks for resistant dextrin. For MCC, focus the LCA on electricity and thermal energy since internal pilots and literature frequently show energy as the dominant hotspot.

Quick deliverables for the pilot:

Energy baseline (monthly metered data aggregated to MJ/kg)

Short cradle‑to‑gate feedstock comparison (corn vs tapioca)

Small‑scale enzyme optimisation and process intensification trials

Low‑impact feedstock sourcing and traceability

Procurement criteria should prioritise: GHG/kg raw starch/cellulose, land‑use risk, transport distance, and supplier certificates (Non‑GMO, organic where relevant). Commercial levers include supplier COAs, local sourcing to reduce freight emissions, and long‑term contracts with feedstock GHG clauses to stabilise carbon intensity and price.

Process technology levers — where engineering reduces footprint

Target high‑leverage process shifts that reduce energy, water and chemical use while improving yields:

Replace batch acid hydrolysis for MCC with intensified routes: continuous reactors (AaltoCell‑style or similar) reduce cycle energy, acid consumption and wastewater volumes.

Evaluate gas‑phase hydrolysis and supercritical CO2 pretreatment for cellulose isolation to lower liquid acid and water demand and reduce wastewater generation.

For resistant dextrin, prioritise enzyme‑first conversions, mechano‑enzymatic pretreatments and closed reactors to lower thermal duty and improve product uniformity.

Implement closed‑loop solvent and acid recovery systems and scale condensate return to reduce steam demand.

Recent LCA evidence for MCC shows gas‑phase hydrolysis can substantially lower energy and wastewater compared with classical aqueous acid methods; pilot testing at Shine Health can validate comparable gains in our plant context.

Utilities, circularity and carbon management

Utilities and circularity measures typically deliver fast payback and clear carbon reductions:

Renewable electricity (onsite solar or wind, or green PPAs) is the highest‑impact lever for MCC and dextrin production.

Electrify thermal loads where feasible (heat pumps, high‑temperature heat pumps) and deploy heat integration and economisers across evaporators and dryers.

Use anaerobic digestion for high‑COD effluent to recover biogas; route recovered heat back into process loops.

Valorise byproducts (cellulose fines into composite feedstock; fermentation coproducts to biogas) to improve economics and circularity.

Governance, targets and KPIs

Set near‑term targets (example: 20% reduction in kg CO2e/kg within 24 months) and report progress with a dashboard of KPIs: kg CO2e/kg, MJ/kg, m3 water/kg, % renewable electricity, % chemical reuse. Prioritise in‑boundary reductions before offsets, pursue ISO 14001 adoption and commission a third‑party LCA for product‑level claims.

Implementation road‑map (0–48 months)

0–6 months — Pilot: meter energy, run short LCA (corn vs tapioca), small‑scale enzyme/process trials. Owners: R&D, EHS, Procurement.

6–24 months — Scale: retrofit or install continuous reactors, electrify boilers/heating, implement heat recovery and wastewater upgrades. Owners: Operations, CapEx teams.

24–48 months — Roll‑out: supplier decarbonisation contracts, product certification, public reporting and product‑level GHG claims.

Offer — how Shine Health can help

Shandong Shine Health can deploy a 0–6 month pilot: energy baseline metering, short cradle‑to‑gate LCA (corn vs tapioca) and focused enzymatic trials to de‑risk scale‑up. For inquiries and technical sampling, contact Henry Liu: info@sdshinehealth.com or WhatsApp +86 134 0544 3339.

References

J. Hosseinzadeh et al., “Sustainable Production of Microcrystalline Cellulose Through Gas Phase Hydrolysis for Pharmaceutical Applications: Characterization and Life Cycle Assessment,” Journal of Polymers and the Environment, 2024.

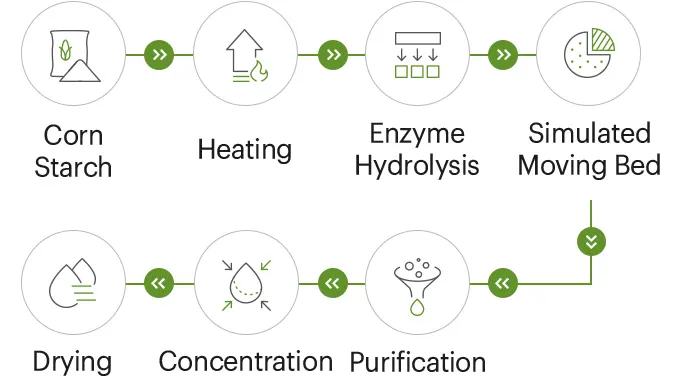

Shandong Shine Health Co., Ltd., product and process pages: resistant dextrin and functional fiber production process, sdshinehealth.com.

IPCC / life‑cycle best practice guidance, selected reviews on energy hotspots in cellulosic ingredient manufacturing.

Case studies on continuous reactor intensification and enzyme‑first processing from recent industrial white papers.

Industry reports on benefits of electrifying steam systems and using heat pumps for process heating.

Operational guidance on wastewater anaerobic digestion and byproduct valorisation in starch‑based processing plants.