3 Fiber-Rich Protein Bar Formulas

Introduction

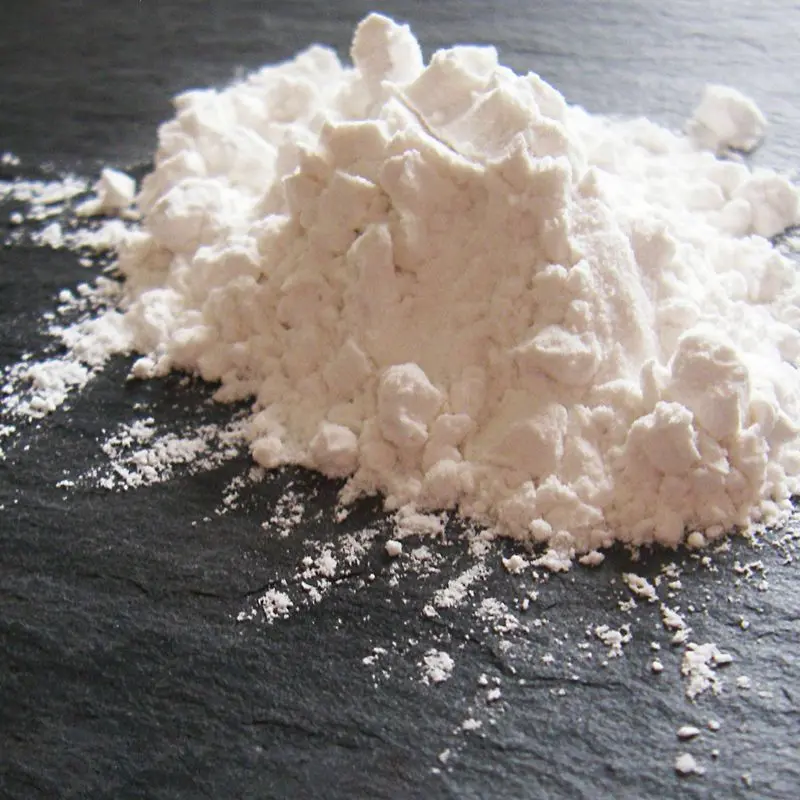

Shine Health’s resistant dextrin (RD) — derived from Non‑GMO corn starch, fiber ≥82%, protein ≤6% — and its complementary soluble corn fiber (SCF) are water‑soluble, heat‑stable functional fibers that act as low‑calorie bulking and binder agents. When used together they allow formulators to reduce simple sugars while preserving chewiness, mouthfeel and structural integrity. The result is practical, manufacturable formulations for chewy high‑protein bars, dense meal‑replacement bars and crunchy low‑moisture bars suitable for commercial pilot runs.

Why use RD + SCF in protein bars

Functional synergy: RD and SCF function as soluble bulking agents, partial humectants and binders. They reduce the need for simple sugars while preserving chewiness and preventing crystalline hardening. Both materials are heat‑ and pH‑stable for cooking, extrusion and slab‑forming processes.

Nutritional positioning: both ingredients raise per‑serving fiber content without adding digestible carbohydrates, enabling lower‑calorie and lower‑glycemic claims (confirm supplier specs for label claims and per‑serving fiber values).

Manufacturing reliability: RD/SCF tolerate typical process temperatures and integrate well with proteins (whey, milk, pea) and carriers (oats, maltodextrin) used in bars.

Production‑ready 10 kg pilot recipes (grams and % w/w)

Notes: recipes assume typical commercial ingredient moisture and solids. Adjust added water/humectant to achieve the listed finished moisture and water activity (aw).

1) Chewy High‑Protein Bar — intermediate moisture, target finished moisture 10–12% (aw ≈ 0.50–0.60)

10,000 g pilot (total)

Whey/pea protein isolate — 2400 g (24.0%)

Resistant dextrin — 1000 g (10.0%)

Soluble corn fiber — 600 g (6.0%)

Rolled oats / maltodextrin (carrier) — 2000 g (20.0%)

Humectant syrup (polydextrose/glycerol syrup) — 800 g (8.0%)

Vegetable fat (emulsified) — 800 g (8.0%)

Reduced‑sugar binder syrup (e.g., isomaltooligosaccharide) — 800 g (8.0%)

Inclusions (chopped nuts/crisp clusters) — 1000 g (10.0%)

Salt, lecithin, flavors, micronutrients — 100 g (1.0%)

Processing highlights: dry premix the proteins and fibers; heat syrup to 65–75°C; combine to homogeneous mass; slab/form at 40–50°C; rest/cool and measure aw at multiple spots before packaging.

2) Dense Meal‑Replacement Bar — moderate moisture, target finished moisture 8–10% (aw ≤ 0.55)

10,000 g pilot

Protein blend (whey + milk/pea) — 2800 g (28.0%)

Resistant dextrin — 1200 g (12.0%)

Soluble corn fiber — 900 g (9.0%)

Rolled oats — 1200 g (12.0%)

Maltodextrin / complex carb — 1000 g (10.0%)

Vegetable fat — 1000 g (10.0%)

Humectant syrup — 500 g (5.0%)

Inclusions (nuts/choco) — 700 g (7.0%)

Minor ingredients (vitamins/minerals/flavor) — 200 g (2.0%)

Processing highlights: use lower free water and compressive forming to achieve a dense structure; consider low‑temperature post‑process drying to reach aw without inducing hardening.

3) Crunchy Low‑Moisture Bar — target finished moisture 3–6% (aw < 0.40)

10,000 g pilot

Protein crisps — 2200 g (22.0%)

Protein isolate — 500 g (5.0%)

Resistant dextrin — 1000 g (10.0%)

Soluble corn fiber — 800 g (8.0%)

Rice crisps / puffed cereal — 2500 g (25.0%)

Fat + sugar binder (coating syrup) — 1800 g (18.0%)

Inclusions — 800 g (8.0%)

Lecithin/emulsifier — 50 g (0.5%)

Flavor/salt — 50 g (0.5%)

Added water for processing — 300 g (3.0%)

Processing highlights: coat crisps with dextrin/syrup binder and tumble to distribute; press and cut; maintain strict humidity control during cooling and packaging to preserve crunch.

Representative lab protocol (chewy bar example)

Dry premix: sift/blend protein, RD, SCF and oats for 5–8 minutes.

Heat syrup: dissolve humectant + binder + 30–50% of processing water; bring to 65–75°C to homogenize.

Add fat + emulsifier to the syrup; allow cooling to 45–55°C.

Add syrup to dry premix in a high‑shear mixer; mix 3–5 min until fully wetted.

Add inclusions at low speed to avoid breakage.

Form by extrusion or slab‑forming; target surface temp 40–50°C.

Cooling & setting: rest at ambient or controlled drying until aw stabilizes; monitor at several points across the slab.

QC and pack: record moisture (halogen/Karl Fischer), aw (aw meter), texture (texture analyzer peak force) and visual appearance.

QC release criteria (examples):

Water activity: within ±0.03 of target aw.

Moisture: within ±0.5% of target (halogen/KF).

Texture: compressive change ≤20% from baseline during shelf intervals.

Microbiology: total plate count and yeast/mold within regulatory limits; absence of pathogens.

Shelf‑life validation & packaging

Accelerated screening: 40°C / 75% RH, sample at 0, 1, 2, 3 months; watch for moisture migration, softening/hardening and rancidity.

Real‑time testing: store at intended commercial conditions for full shelf study.

Packaging: select moisture‑barrier films with robust seals for intermediate‑moisture bars; for crunchy low‑moisture bars, use high‑barrier pouches with desiccant if needed.

Scale‑up tips and implementation

Ingredient dispersion: preblend RD/SCF with protein and carrier to avoid clumping; ensure adequate shear during wet‑mixing for uniform binding.

Humectant balance: use humectants (glycerol, polydextrose) to control softness and limit water activity-driven hardening.

Heat sensitivity: RD/SCF are heat‑stable but monitor protein denaturation when using high process temperatures.

Pilot sampling: measure aw, moisture and texture at multiple slab locations to validate homogeneity before larger runs.

Conclusion & next steps

Using resistant dextrin and soluble corn fiber provides a practical path to reduced‑sugar, high‑fiber protein bars that retain consumer‑preferred texture. The three pilot formulas and the workflow above are production‑ready starting points; for custom label targets, finished moisture and nutritional claims, consult ingredient specifications and perform pilot stability testing.

Contact Shine Health for samples, technical support and ODM options: info@sdshinehealth.com

References

Loveday SM, Hindmarsh JP, Creamer LK, Singh H. Physicochemical changes in a model protein bar during storage. Food Res Int. 2009;42(8):1107–1114.

Loveday SM, Hindmarsh JP, Creamer LK, Singh H. Physicochemical changes in intermediate‑moisture protein bars made with whey protein or calcium caseinate. Food Res Int. 2010;43(5):1395–1403.

Hartel RW, von Elbe J, Hofberger R. Confectionery Science and Technology. Springer; 2017.

Gibbs G. Accelerated shelf life of a health bar contained in different bio‑based packaging materials. 2015.

Brander RW. Cereal bars and methods of their manufacture. Patent application; 2017.

Product data and images: Shandong Shine Health Co., Ltd. product pages and technical materials (resistant dextrin, soluble corn fiber).